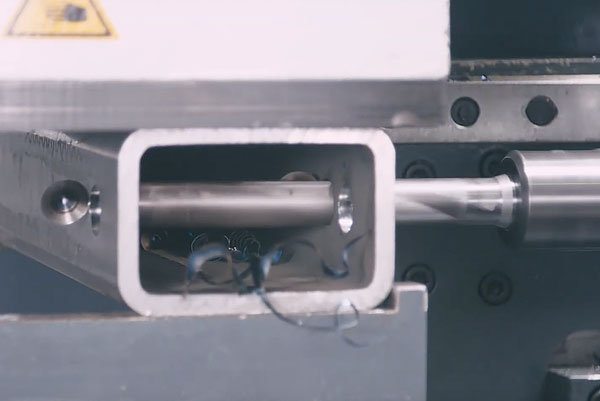

Cnc Drill Line End Mill

Voortman technicians will complete the installation and calibration of your machine. After that, he'll spend time with operators and guide them through our comprehensive training program. Training will be given to your operators in:

Automatic Edge Finder - The edge locater can be used either manually (Jogging Mechanism & Screen Buttons), programmatically or completely automated (dedicated programs). This option adjusts the offsets and rotation of the program to match the cutting table's orientation.